CASE STUDY : LITURGICAL VESSELS

A step-by-step process illustrating the entire scope of a project;

research

drawings

prototypes & samples

fabrication

education

results

In 2008, I was commissioned by a parish in St. Paul Minnesota to design and build a series of new altar vessels in the Arts & Crafts style. A total of 9 pieces were hand wrought in copper and plated with sterling silver including four chalices, three patens, a ciborium and a decanter.

RESEARCH- 4 STEPS

1. I began by meeting with the liturgy committee and identifying what they wanted by using their current vessels as the departure point. We discussed the ceremonial role of each vessel, the interaction, and the physical attributes such as weight, size, shape and liquid capacity. One of the most compelling requests was that the chalices be suitable for people with small or weak hands– a principle that would end up governing all of the vessels. This pushed me to investigate how shape influences grip and how texture can be applied to promote grip. Following each meeting, I would immediately sketch ideas to digest the feedback and generate new options.

2. Vessels have been essential to survival and sacrament for thousands of years; continually made, adorned, used, and revered. There is no limit to the depth of research into the history of a cup or container. Some rare examples were discovered in auction catalogues, appraisal books, and sources pertaining to the grammar of ornament. I also researched liturgical vessels that are currently mass produced and vessels that are custom made by silversmiths today.

3. Hollow-ware is a specific type of metalsmithing that was completely new to me so I began learning the craft and principles required to hammer sheet metal into hollow forms. I studied numerous technical and reference books, demonstration videos, websites, and practiced on many pieces in copper sheet.

4. The vessel's design was to follow suit with the church's architecture and interior built in the Arts & Crafts style. Unlike Gothic churches, in the Arts and Crafts style elaborate adornment was to be avoided and symbolism was to be modest. I studied the work of architects like Greene and Greene, Frank Lloyd Wright and E. Fay Jones for visual and conceptual development before deciding that the stain glass window in the sanctuary would be the root source of ornamentation for all of the vessels.

DRAWING

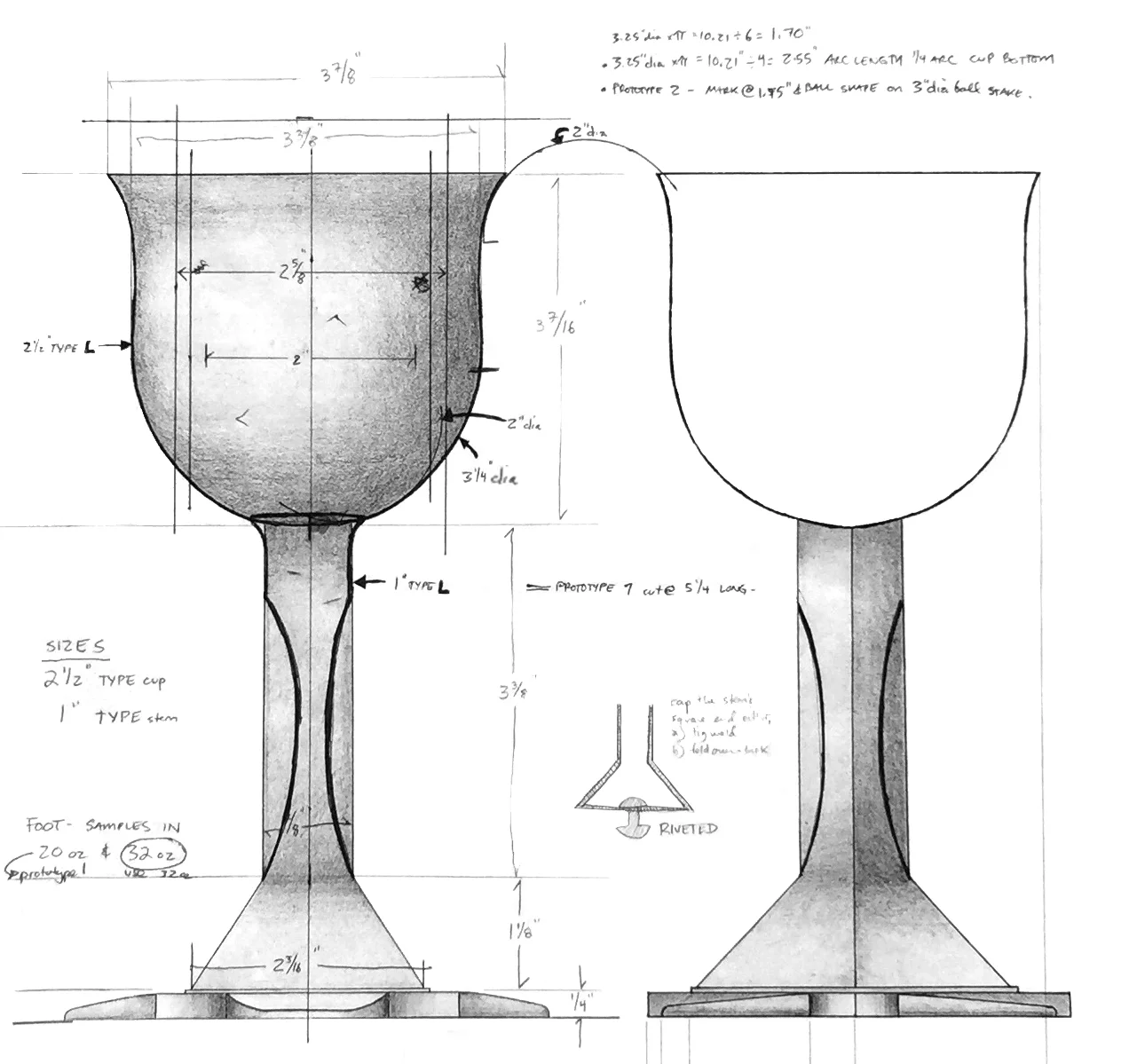

The drawing phase is a generative process that distills research and creates options. I determined the size of the chalice cup; considering both the capacity of liquid it needed to contain and people's feedback on what was favorable to hold, pour and sip from. Next, the size of the chalice stem was considered, followed by it's foot. I then created proportional grid paper to allow each sketch option to yield the same capacity of liquid (far left photo). Each vessel was drawn with this approach and illustrated in a series of three subtle variations (lower right image).

As my science and arithmetic teachers would say, it is important to show your work. The lower left image shows hand-written notes based on the samples and prototype. The final presentation to the liturgy committee included graphite drawings in full scale accompanied by prototypes of the copper chalice and paten in full scale.

SAMPLES / PROTOTYPES

Quite commonly, blacksmiths create their own tooling. To shape these vessels, I made dozens of special tools, dies, and fixtures that could withstand continual impact from hammering the copper sheet into shape. From hardened steel punches, hammers and anvil stakes to steel and polyethylene dies, these implements were necessary to craft these unique vessels.

A full scale paten and chalice prototype was hammered out to determine the projects budget and timeline. When brought to committee meetings, these pieces were powerful in communicating just how the vessels could feel and look so to eliminate any uncertainty or surprises when the project was finished and delivered.

FABRICATION

During the process of forming the prototype bowl and chalice, I meticulously recorded notes during each step. This allowed me to rapidly learn the behavior of the metal, provide an accurate estimate of time and cost, and effectively produce multiple pieces with consistent quality and shape.

It requires tens of thousands of hammer swings to repeatedly coax the metal from flat into a volumetric shape. By nature, this process called ‘raising’ is a slow or gradual sequence of repetitive impact. In an attempt to count the exact number of strikes to raise the paten, I destroyed a pedometer by strapping it to my hammer.

EDUCATION

Sharing what goes on behind the scenes with the clients provides them with a deeper understand of the project and a heighten sense of ownership in the end. I arranged studio visits, demonstrations and presentations at various times throughout this commission.

RESULTS

The finished copper vessels were plated in sterling silver and mirror polished. A fastening system was used between the cup and foot so that each chalice could be dissembled into three parts for ease of plating, cleaning and repair. Below are selected photos of the finished chalices, ciborium and the vessels being used during ceremony.

A few weeks after delivery, I gave a presentation to the parishioners, at large, to describe the process and to answer their questions. It was the highlight of this very special commission. To everyone that makes up the community of Saint Cecilia, I thank you!

Sincerely,

ChristopheRand